Column Packing and Preparation for Affinity Chromatography of GST-tagged Proteins

This appendix provides column packing guidelines for affinity chromatography media. Efficient column packing is essential for a good separation, especially when using gradient elution.

A poorly packed column gives rise to poor and uneven flow, peak broadening, and loss of resolution. Prepacked GST columns from Cytiva will ensure reproducible results and the highest performance. If column packing is required, the manufacturer's instructions should be consulted. The following guidelines apply at all scales of operation. The following parameters should be chosen before packing a column.

Selecting Column Size

When using an affinity binding technique, or when using a low flow velocity, select short, wide columns (typically 5 to 15 cm bed height) for rapid purification.

Selecting Amount of Medium

The amount of chromatography medium required depends on the medium's binding capacity and the amount of sample to be purified. GST media are supplied with instructions detailing the binding capacity per ml of medium. Estimate the amount of medium required to bind the target protein and use two to five times this amount to pack the column. An excess of medium is used to ensure a maximum binding of the sample, since the binding capacity is influenced by the nature of the sample and may differ between different samples.

GST media can be packed in Tricorn™, XK, or HiScale™ columns available from Cytiva.

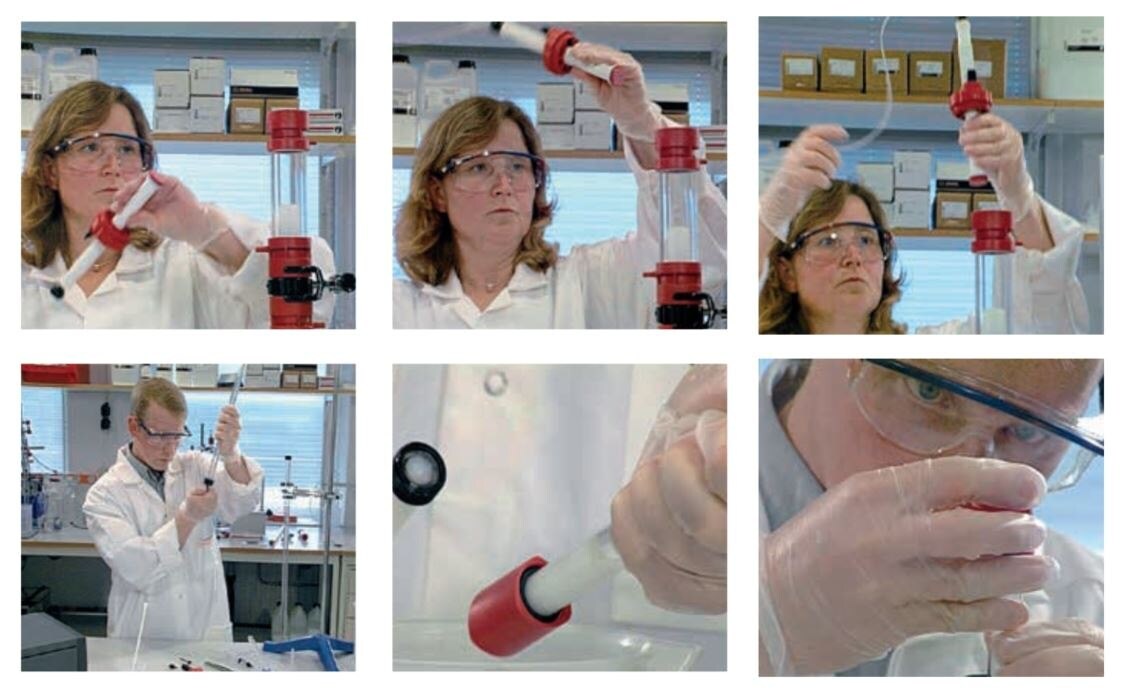

Figure 1.Step-by-step demonstration of column packing.

Selecting Column Type

Tricorn, XK, and HiScale columns are fully compatible with the high flow rates allowed with GST media, and a broad range of column dimensions are available (Table 1). In most cases the binding capacity of the medium and the amount of sample to be purified determine the column size required. Also, empty disposable PD-10 columns are available for single-use applications using gravity flow.

1 All Tricorn and XK column specifications are valid when one adapter is used. All HiScale specifications are valid when two adapters are used.

2 For gravity-flow applications. Together with LabMate Buffer Reservoir, up to 25 ml of buffer and/or sample can be applied.

Column Packing Procedure

This procedure describes column packing in 20% ethanol. Packing can also be performed in water or buffers. However, the advantage of packing in 20% ethanol is that no decanting and exchange of storage solution is needed (simplified handling). In addition, the column can be stored in the 20% ethanol until use.

The medium is supplied preswollen in 20% ethanol and has a slurry concentration of 75% (settled medium).

- Equilibrate all materials to the temperature at which the packing is to be performed.

- Eliminate air by flushing the column end pieces with 20% ethanol. Ensure that no air is trapped under the column net. Close the column outlet leaving 1 to 2 cm filled with 20% ethanol in the column.

- Gently resuspend the medium. (Avoid using magnetic stirrers because they may damage the matrix.)

- Estimate the amount of slurry (resuspended medium) required. Example for a bed volume of 5 ml: use 6.7 ml of slurry (5 ml divided by the slurry concentration 0.75). Add additional 20% ethanol to achieve a 1:1 ratio of settled medium and overlayed 20% ethanol (= slurry concentration ~50%), and mix gently.

- Pour the resuspended volume of the slurry into the column. Pouring down a glass rod held against the wall of the column will minimize the introduction of air bubbles.

When the slurry volume is greater than the total volume of the column, connect a second glass column to act as a reservoir. This ensures that the slurry has a constant diameter during packing, minimizing turbulence and improving the column packing conditions.

- Fill the column with 20% ethanol immediately.

- Mount the column top piece and connect to a pump.

- Open the column outlet and set the pump to the desired flow rate (Tables 2 to 4).

If the recommended flow rate is higher than the pump capacity, use the maximum flow rate that the pump can deliver. Do not exceed the maximum operating pressure of the medium or column.

- Maintain the packing flow rate for at least 3 column volumes and after a constant bed height has been obtained. Mark the bed height on the column.

- Stop the pump and close the column outlet. Remove the top piece (and the second glass column if that has been used) and carefully fill the rest of the column with 20%ethanol to form a convex surface at the top.

- Insert the adapter into the column at an angle, ensuring that no air is trapped under the net.

- Slide the adapter slowly down the column (the outlet of the adapter should be open) until it reaches to the mark. Lock the adapter in position.

- Connect the column to the pump and set the pump to the desired flow rate (Tables A6.2 to A6.4). Reposition the adapter if necessary. The column can be stored in 20% ethanol until use.

Before the first chromatography run: Wash the column with 5 column volumes of water followed by 5 column volumes of binding buffer (see maximum flow rate, Table 5).

Recommended Flow Rates During Column Packing |

|---|

Max operating pressure:

1 100 bar

2 50 bar

3 5 bar

4 20 bar

5 3 bar

Max operating pressure:

1 100 bar

2 50 bar

3 5 bar

4 20 bar

5 3 bar

Max operating pressure:

1 100 bar

2 50 bar

3 5 bar

4 20 bar

5 3 bar

To continue reading please sign in or create an account.

Don't Have An Account?