919632

TissueFab® bioink

(GelHA)ma -UV/365 nm

Synonym(s):

Bioink, HAMA, Hyaluronic acid, Hyaluronic acid methacrylamide, Hyaluronic acid methacrylate, Hyaluronic acid methacryloyl, Sodium hyaluronate

About This Item

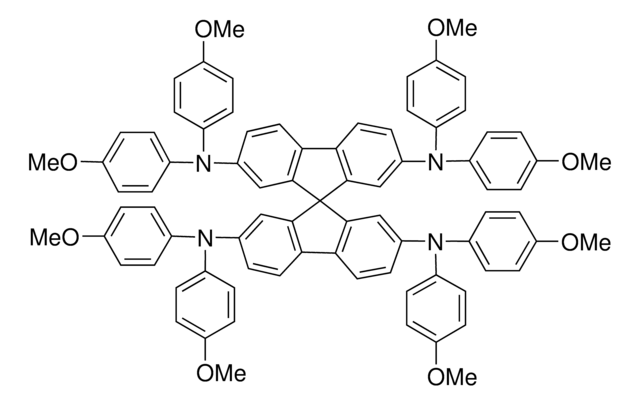

Recommended Products

Quality Level

description

suitable for 3D bioprinting applications

sterility

sterile-filtered

form

viscous liquid

impurities

≤5 CFU/g Bioburden (Fungal)

≤5 CFU/g Bioburden (Total Aerobic)

color

colorless to pale yellow

particle size

0.2 μm

pH

6.5-7.5

application(s)

3D bioprinting

storage temp.

2-8°C

Looking for similar products? Visit Product Comparison Guide

Related Categories

Application

Packaging

Legal Information

Storage Class Code

10 - Combustible liquids

WGK

WGK 3

Certificates of Analysis (COA)

Search for Certificates of Analysis (COA) by entering the products Lot/Batch Number. Lot and Batch Numbers can be found on a product’s label following the words ‘Lot’ or ‘Batch’.

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Articles

Bioinks enable 3D bioprinting of tissue constructs for drug screening and transplantation; select suitable bioinks for specific tissue engineering.

Learn how 3D bioprinting is revolutionizing drug discovery with highly-controllable cell co-culture, printable biomaterials, and its potential to simulate tissues and organs. This review paper also compares 3D bioprinting to other advanced biomimetic techniques such as organoids and organ chips.

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service