Graphene for Rechargeable Batteries

Francesco Bonaccorso, Vittorio Pellegrini

Istituto Italiano di Tecnologia, Graphene Labs

Material Matters, 2016, 11.1, 15

Introduction

Advanced technologies for energy conversion and storage are widely sought after for their potential to improve consumer and electronic device performance as well as for the prospect of reducing the societal and environmental impact of energy generation. Rechargeable batteries already power a wide range of applications from portable electronics to automotive systems.1 But these applications are still hindered by battery performance limitations that include inadequate power and energy density, limited lifetime, slow recharging, high cost, and limitations in battery shape and physical flexibility. In order to address these challenges, novel materials for anodes and cathodes will be required. Lithium-ion batteries (LIBs) currently dominate the market,2 with most commercial LIBs comprised of a LiCoO2 cathode on aluminum substrate and a graphite anode on copper. This configuration yields a theoretical specific energy density of 387 Wh kg–1 and a measured energy density of 120–150 Wh kg–1,3 much higher than what can be achieved by other battery types such as lead acid (~30 Wh kg–1)4 and nickel metal hydrides (45–68 Wh kg-1).1 Other promising oxide host structures identified but not yet commercialized in batteries include layered Li1–xMO2 (M = Ni, Mn, Co),5 spinel LiMn2O4,6 and ordered olivine Li1-xMPO4 (M = Fe, Mn, Ni).7

Graphene and several related two-dimensional (2D) crystals can boost the performance of LIBs and improve cyclability either as stand-alone materials8,9 or when integrated with other materials to form functional composites.10,11 Besides graphene, a number of 2D crystals have recently been investigated, including transition metal dichalcogenides (TMDs),12 transition metal oxides (TMOs),13 layered double hydroxides (LDHs),14,15 and MXenes.16 Among these new materials, graphene-silicon nanoparticle (NP) composites show significant promise and have attracted substantial attention.17 The theoretical reversible specific capacity of silicon, measured as the total ampere-hours per gram (mAh g–1) available during controlled discharge, approaches 4,000 mAh g–1,18 one of the highest values among potential anode materials. However, silicon and nanostructured siliconbased anodes also suffer from material degradation and significant capacity fading due to volume contraction and expansion during the charge/discharge cycling.19 This issue can be limited by using graphene to fabricate hybrid anodes where graphene secures well-dispersed particles and forms a conductive matrix between them.

The potential of graphene and other 2D crystals20 is not limited to conventional lithium-ion batteries. Sulfur-, tin-, sodium-, and zinc-based batteries can also benefit by the incorporation of 2D crystals from a cost perspective, potentially allowing them to compete with lithium-ion technology.21 Graphene and other 2D crystals also can be used to improve the electrochemical performance of Li-air batteries.22,23 For example, the incorporation of porous reduced graphene oxide (RGO) results in the highest stability achieved in such an electrode, and is a very promising early utilization of RGO technology.19 However, further studies are needed to assess reproducibility and scalability.19,21

The role of graphene and other 2D crystals is not limited to improving reversible specific capacity or specific energy density in batteries.10 In fact, graphene can be used to form conductive films to replace metal supports both in cathodes and anodes, reducing overall battery weight. Thus, the exploitation of graphene and other 2D crystals can allow for the development of conformable and transparent batteries with enormous potential for wearable electronics,24 smart tissues,25 and biomedical applications like implantable prosthetic devices in the long-term.11

Much of the current research is focused on developing a clear understanding of the charge storage mechanism of graphene, other 2D crystals, and their composites in order to limit irreversible processes.16,21 Subsequently, the ability to go into commercial application of these 2D materials will be linked to exceptional and consistent morphology, electrical properties, purity, and cost.26 In the next few years it will be crucial to determine the best lab-scale solution that can effectively be scaled up to develop viable commercial products.

We present a comprehensive review of the current state of the art of graphene and other 2D crystals used in the development of nextgeneration batteries, outlining the key issues to be explored in an effort to identify future directions. We also discuss how the versatility of 2D crystal-based technology can boost the development of new power management solutions for portable and flexible devices.

Production of 2D Crystals for the Fabrication of Functional Electrodes

One of the most important material requirements for developing energy storage devices, and batteries in particular, is the combination of high specific surface area (SSA)27 and high electrical conductivity (σ)28 associated with the prospect of large scale manufacturing.26 Twodimensional crystals that meet such requirements can be produced by bottom-up29,30 and top-down11,13,26 techniques, offering complementary opportunities for renewable energy technologies. Here, we briefly focus on liquid phase exfoliation (LPE), a production strategy that is both affordable and highly scalable, making it appropriate for batteries and other energy devices.

Liquid Phase Exfoliation

Direct exfoliation of layered crystals (Figure 1A) in solution20 is considered a preferred production route for energy applications because of its low cost, scalability, and potential for functionalization. The exfoliation of layered crystals is usually carried out via ultrasonication (Figure 1B)8,13,20,26,31–33 in water with the aid of surfactants/polymers,31,32 or in organic solvents.8,9,34,35 Other exfoliation approaches such as shear mixing,37 ball milling,38 as well as electrochemical processes39,40 have been proposed as alternative scale-up methods.

Figure 1. Process chain from the exfoliation of bulk-layered crystals to functional inks. A) Layered bulk crystals. B) Exfoliation of layered crystals by ultrasonication. C) Photograph of different 2D crystal inks.

After exfoliation, the obtained dispersions are “purified” via ultracentrifugation41 in order to separate exfoliated and unexfoliated flakes. This ultracentrifugation is also a powerful tool for the separation of large, thick34 flakes from small, thin8,31,32,35 flakes.

A high concentration of 2D crystals in solution is desirable for the largescale production of composites42 and inks31 used in the fabrication of functional electrodes for battery applications (Figure 1C). Following ultracentrifugation, a concentration of ~15 mg/mL for graphitic sheets32 and ~40 mg/mL for MoS2 43 flakes can be achieved. A dispersion highly enriched by single-layer graphene (SLG) is achieved by sonication and ultracentrifugation in water-surfactant dispersion in a uniform (SLG ~60%)31 and a density gradient (SLG ~80%)32 medium. Surfactants39 and polymers44,45 allow for improved control of the morphological properties (lateral size31 and thickness32) of the dispersed flakes and also help to avoid aggregation—the main factor limiting the SSA of the as-produced materials. However, a high SSA also brings disadvantages when the material is used in batteries. For example, high SSA favors the formation of solid electrolyte interphase and leads to very high initial irreversible capacity.14,46 Moreover, the presence of surfactants/polymers is not optimal for device integration, especially when preservation of the pristine electronic properties of the flakes is important, e.g., in LIB electrodes. The presence of surfactants and/or polymers decreases the inter-flake connectivity, strongly affecting the σ of the electrodes.23 One significant disadvantage of the LPE of 2D crystals is a reliance on solvents with high boiling points, high toxicity, and/or incompatibility with deposition onto current collectors such as copper and aluminum. To overcome such limitation, LPE of 2D crystals has recently been carried out in a mixture of low boiling point solvents47 such as water/ethanol45,47,48 or water/isopropyl alcohol.47 By adjusting the relative concentration of the co-solvents, it is possible to tune the rheological properties such as density, viscosity, and surface tension of the 2D crystal dispersions/inks. LPE is also utilized to create dispersions of graphite intercalated compounds49 formed by periodic insertion of atomic or molecular species (intercalants) between graphite layers50 and is largely used in LIBs.46 Graphite intercalated compounds can be processed with donor or acceptor intercalants to yield highly conductive materials (σ = 6.3 × 105 S cm–1).51 Moreover, tunability of the interlayer spacing (e.g., from 0.53–0.59 nm with potassium, rubidium, or cesium up to ~0.9 nm with dimethylsulfoxide52) permits the accommodation of large amounts of lithium ions.

LPE can also be exploited to produce graphene oxide (GO).53 Graphene oxide contains extended aromatic frameworks and multiple functional groups such as hydroxyl or epoxide groups with carboxylic or carbonyl groups attached to the edges.54 These functional groups render GO readily dispersible in water and other common solvents, and provide reaction sites for chemical modification,53 i.e., covalent attachment of organic and inorganic nanoparticles. Several processes have been developed to chemically reduce or decrease the oxidation state of the oxygen-containing groups in the GO flakes.55 Even though RGO does not achieve the same σ as pristine graphene,55 it is still widely being explored by researchers for the fabrication of electrodes for lithium-ion and other technologies.10 Unfortunately, the reduction state strongly influences the final electrochemical performance of RGO as an anode material. Indeed, the further removal of functional groups during battery operation results in a re-stacking of the graphene layers, reducing the storage capacity and, thus, reversible capacity during cycling.56

Storage Mechanisms and Current State-of-the-Art Electrochemical Performances

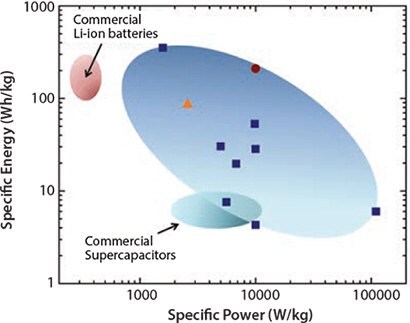

LIBs are based on the capture and release of lithium ions.1–3 Current LIBs are typically composed of an intercalated lithium compound cathode (e.g., LiCoO2 or LiFePO4), a graphitic anode, and an electrolyte.1–3 During the charging mode, lithium ions travel from cathode to anode through the electrolyte upon application of an external electrical potential.1–3 In the reverse process, lithium ions are extracted from the graphitic electrode and migrate toward the cathode.1–3 Electrons traveling in the external circuit can be used to power devices and perform external work.1–3 The gravimetric capacity to store lithium ions (i.e., the weight percentage of stored lithium per gram of battery weight) is crucial to the performance of these rechargeable batteries. Compared with graphite, graphene and other 2D crystals have a larger theoretical gravimetric capacity.18 Additionally, the use of graphene provides additional flexibility that enables further development of bendable and stretchable battery devices.57 Other relevant properties of 2D crystals are their high σ, and the electrochemical and thermal stability within the operational temperature range (–50/100 °C). LIBs are ideal for applications in which high energy density (~200 Wh kg–1, typically more than one order of magnitude larger than that of supercapacitors, Figure 2) is needed.

Figure 2. Ragone-like plot58 showing energy (Wh/kg) vs. power (W/kg) densities for batteries and supercapacitors. The blue ellipse encloses the region of energy/power density values of available 2D crystal-based storage devices. Inside the ellipse, the circular dot refers to a lithiumion battery,59 the orange triangle to a hybrid supercapacitor-battery,60 and the blue squares to supercapacitors.61 The smaller wine and cyan elliptic areas refer to values for commercial LIBs62 and supercapacitors,61 respectively. It is important to stress that it is problematic to compare packaged commercial cells (the mass includes the electrodes/package/electrolyte with performance measured using industry standards) with 2D crystal-based devices considered for the plot that include only the electrode material. When packaging and measurement methods are accounted for, these devices could have lower energy and power densities than shown on the diagram.

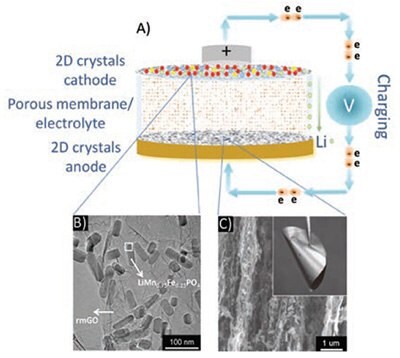

2D Crystals as Cathode and Anode Materials in LIBs

Graphene and other 2D crystals are emerging as promising materials for both anodes8–10,63 and cathodes64 in LIBs (Figure 3A). For example, graphene and other 2D crystals can be used as an electrically conductive support for cathode nanomaterials such as olivine-type phosphates (consisting of a hexagonal closed-packing of oxygen atoms with Li+ and M2+ cations located in 1/2 of the octahedral sites and P5+ cations in 1/8 of the tetrahedral sites),65,66 with low σ (~10–8 S cm–1).67 This is because electrically conductive 2D crystals such as graphene and RGO (Figure 3B) facilitate electron transport between conductive 2D crystals and cathode nanomaterials, allowing the fabrication of electrodes with higher electrochemical performance.63

Although a conductive 2D crystal matrix can enhance the σ of a composite material and improve the rate capability compared to bare cathode materials,65 the method of composite fabrication is fundamental to the final electrochemical performance of the resulting cathode. In fact, it has been shown that mixing RGO according to the standard procedure used for carbon black can actually reduce Li+ mobility, affecting the electrochemical performance of the hybrid cathode.68 Several attempts to engineer the hybrid cathode material with RGO as an electrically conductive support have been carried out.69 LiMn1–xFexPO4 nanorods grown on RGO flakes show a reversible specific capacity of ~100 mAh g–1 at the rate of 50 C, with stable operation, i.e., 1.9% degradation for 100 cycles.65 A similar approach to create hybrid electrodes was applied to different materials, such as spinels like LiMn2O4.69 The hybrid RGO/ LiMn2O4 cathode shows a high specific capacity of 137 mAh g–1 at 1 C rate (a measure of the speed at which a battery is discharged relative to its maximum capacity), with remarkable performances also at faster charge/ discharge rates of 50 C and 100 C, delivering discharge capacities of 117 mAh g–1 and 101 mAh g–1, respectively.69

RGO is currently one of the most commonly used 2D crystal materials deployed in LIB anodes (Figure 3C).70 During the first cycle, the RGO anode can display capacities well above the theoretical limit of SLG. However, this large initial capacity is linked to the irreversible reduction of the electrolyte and the formation of a surface passivation layer likely favored by the presence of large amounts of structural defects and functional groups.26,53–55 A reversible specific capacity of RGO-based electrodes of 540 mAh g–1,70 far below the theoretical value of graphene,10 has been demonstrated.

More recently, graphene flakes produced by LPE of pristine graphite have been used for the preparation of anodes.9,10 Edges and defects can potentially act as reversible storage sites of Li, contributing to the reversible specific capacity of the graphene-based electrodes. Graphene electrodes show faster C rates61 with respect to graphite, mainly due to decreased energy barriers for lithium diffusion at the graphene flake edges.8,71 Hassoun et al. have demonstrated a reversible specific capacity of ~750 mAh g–1 with a current density of 700 mA g–1 using an anode made of exfoliated graphene flakes with a lateral size finely tuned to less than 100 nm.8 This configuration resulted in the uptake of lithium ions both on the basal planes and on the edges of the flakes.8 The graphene flake-based anode shows optimal performance in a full cell configuration, achieving a reversible specific capacity of 165 mAh g–1 and an estimated energy density of ~190 Wh kg–1, with stable operation for over 80 charge/ discharge cycles.8 Graphene flakes produced by LPE have also proven to be effective anode materials in a binder-free configuration, achieving a reversible specific capacity of ~500 mAh g–1 after 100 cycles at a current density of 100 mA g–1, with a coulombic efficiency of >99.5%.9

Graphene and other 2D crystals have also been used for hybrid anode fabrication to increase the charge/discharge capacity of LIBs by mixing electrochemically active particles such as alloy-type anodes,72 silicon,73,74 sulfur,75 Co3O4,76 Li3VO4,77 Fe3O4, 78 with graphene and other 2D crystals.

Figure 3. Representative strategies for graphene and 2D crystal-based battery electrodes. A) Schematic of a battery consisting of graphene and 2D crystal electrodes (anodes and cathodes) in a charging state. B) Graphene as substrate for the growth of electrochemically active materials for lithium-ion batteries.65 C) Hybrid GO/silicon composite electrode.79

Both graphene flakes and RGO can suppress NP aggregation by accommodating their volume expansion/contraction upon lithiation/ de-lithiation while supplying high conductivity to the hybrid anodes. As a consequence, the reversible specific capacity and cycling performance of hybrid anodes, such as graphene/Co3O4,73 RGO/sulfur,80 RGO/Li3VO4,74 and RGO/Fe3O4 75 can be greatly improved compared to electrodes made of these NPs alone.

Other 2D crystals, such as TMDs,81 TMOs,82 and transition metal hydroxides (TMHs)83 are also promising lithium-ion battery materials due to their fast ion conductivity and ability to intercalate lithium ions.16 For example, a reversible specific capacity of ~800 mAh g–1 and ~470 mAh g–1 has been demonstrated for MoS2 78 and WS2 84 anodes, respectively. ZrS2 colloidal nanodisks with a diameter of ~20 nm delivered a reversible specific capacity of ~600 mAh g–1.85 A hybrid WS2/RGO composite was used as an electrode and achieved a reversible specific capacity of ~240 mAh g–1 at a high current density up to 4 A g–1.86 Among TMOs, lithiated MoO3 nanobelts show a specific capacity of ~220 mAhg–1 at a current density of 30 mAg–1 after 15 cycles, with a capacity retention of 92%.87 However, the lithiation process is not yet fully understood, with the interaction of lithium ions with the oxygen atoms controlling the reversible and irreversible intercalation/uptake processes.

Other Technologies (Air, Sodium, Flexible)

Lithium Air

Lithium-air batteries, commonly composed of metallic lithium and oxygen (or air) as anode and cathode, respectively offer a theoretical energy density of 5,200 Wh kg–1,88 much higher than what is achievable using metal-ion batteries.2 This high theoretical energy density results from the pairing of lithium and oxygen from air89 and makes lithium-air batteries one of the most promising technologies for the development of nextgeneration batteries.

However, despite a promising theoretical energy density, lithium-air batteries have a number of performance issues that must be addressed before successful commercialization. These limitations include short lifetime, limited rate capability (e.g., only about 100 cycles), and low energy efficiency. The morphology of the cathode (air electrode) is currently believed to be a critical limiting factor to the improved performance of lithium-air batteries. In fact, both the porosity and SSA of the cathode determine the morphology and amount of the reduction products resulting from the discharge process.

Incorporation of graphene and other 2D crystals has shown promise in addressing the limitations of lithium-air batteries and improving their performance. For example, RGO used as a cathode material can deliver higher capacities than other carbon substrates.90 In particular, the use of RGO in combination with other catalysts such as RuO2・0.64H2O-RGO hybrids91 in lithium-air battery cathodes is very promising. This intriguing combination results in a reversible specific capacity of 5,000 mAh g–1 at a charge potential of ~3.7 V and high current density of 500 mA g–1.89 A very recent work has shown that RGO electrodes can help reversibly form and remove crystalline LiOH during discharge and charge, leading to high specific capacity and improved rechargeability.92

Sodium Ion

Since sodium is a more abundant element than lithium, sodium-ion batteries have the potential to become a cheaper alternative to lithiumion batteries. Graphite, the most common anode material in lithium-ion technology, however, is not a suitable active anode material for use in sodium-ion batteries. Because of its large ionic radius, Na+ ions do not intercalate into graphite.93 This drawback is stimulating research aimed at exploring the use of graphene-based materials in which the interlayer distance can be tuned and optimized for Na+ intercalation and up-take.93 Promising results have been obtained with RGO, yielding a specific capacity of ~100 mAh g–1 at a current density of 200 mA g–1 after 250 cycles.94 Moreover, anodes made by highly ordered graphitic structures with a large graphene interlayer spacing have reached a specific capacity of ~300 mAh g–1 at a current density of 50 mA g–1 after 10 cycles, reinforcing the crucial role of interlayer spacing in graphene-based anodes for sodium ion batteries.95 However, the use of graphene and 2D crystals in sodium-ion batteries, both as active anode materials and as an electrical support at the cathode, is at an early stage. More extensive research is needed to define the effectiveness of this approach.

Flexible Batteries

The development of flexible and/or stretchable battery devices96 is strongly dependent upon the development of flexible electrodes with robust mechanical properties. Such devices must be able to accommodate significant strain22 while retaining their function. These next-generation batteries must also have high reversible specific capacity and energy efficiency coupled with a long cycle life and low cost. These requirements make the development of flexible batteries particularly challenging using current technologies. In fact, the process used to prepare a conventional electrode, including the steps of mixing those compositions (i.e., active material, carbon black and binder), coating the mixture onto the current collector, post-drying, and pressing, is time-consuming and expensive. In addition, the post-drying (annealing) process poses a strong limitation due to the small temperature range the substrate itself can sustain to fabricate flexible electrodes or flexible supports. Moreover, a flexible electrode must contain the precise amount of binder and carbon black90 in order to obtain good flexibility, σ, as well as adhesion between the electrode and the current collector. In this context, it is necessary to envisage novel materials and production processes for the fabrication of electrochemically performant flexible electrodes.

Graphene and other 2D crystals may be a viable strategy for the realization of a flexible and stretchable battery. For example, layer-bylayer assembly of a 3D flexible conducting scaffold loaded with silicon nanoparticles showed a reversible specific capacity of 1,100 mAh g–1 at a discharge current of 8 A g–1.91 The device was also tolerant to structural deformation.97

Cheng and co-workers57 demonstrated a thin, lightweight, flexible lithium-ion battery based on a flexible, conductive, interconnected 3D graphene foam network produced by chemical vapor deposition. The foam network served as both a highly conductive pathway for electrons/ lithium ions and as a lightweight current collector. After filling the 3D graphene foam with active materials leading to LiFePO4/graphene and Li4Ti5O12/graphene electrodes as cathode and anode, respectively, a flexible battery was demonstrated.57 The assembled battery operated at a voltage of 1.9 V, with an initial discharge capacity of ~143 mAh g–1 and a coulombic efficiency of 98% at a 0.2 C rate.57 The 3D graphene foams replaced various inactive components of the battery such as the metal current collectors, conducting additives, and binders.57

The development of such flexible batteries is still at an early stage, and the inclusion of graphene and other 2D crystals into different components of the battery57 is even more recent. There is still a long way to go before a reliable solution for the fabrication of transparent and flexible batteries based on graphene and other 2D crystals is identified. Without doubt, a transparent and flexible battery has the potential to deeply impact many areas of technology and consumer products. For example, a flexible and transparent battery could be coupled with computer/smart phone/PDA displays to make more compact and user-friendly electronics, integrating hidden energy harvesting and storage capability. Another example, conceptual products such as flexible and transparent communication devices, biosensors, and other concepts are now highly limited by rigid and opaque batteries, likely the most difficult component to make flexible and transparent at the same time. Batteries with conformable configurations will be very important to fit into the next generation of electronics with different form factors, and here graphene and 2D crystals could play a key role.

Perspective

Graphene and other 2D crystals have the potential to impact practical energy storage systems such as LIBs by increasing their energy and power densities, cyclability, and cost, as well as enabling the development of next-generation batteries such as lithium-air and flexible batteries. However, there are many issues that still need to be addressed, and there is ample room for significant breakthroughs in the field. While promising results at the laboratory level are creating high expectations, the gap between laboratory-scale research and commercial applications based on 2D crystals has yet to be closed. The challenges ahead are linked to the refinement of the production methods to better understand and control fundamental issues such as lithium adsorption and solid electrolyte interface formation, the role of lateral sizes and number of layers of the flakes, optimization of graphene-based composites, and fine tuning inter-layer distances of the 2D crystals flakes through appropriate functionalization of the flakes themselves, with the aim to push storage densities and cyclability to the highest possible values. Another challenge is the scale-up and manufacture of these emerging technologies. These listed here are some of the goals to reach before 2023, as set by the European Graphene Flagship.11

Acknowledgments

The authors acknowledge Bruno Scrosati, Reza Fathi, Simone Monaco and Haiyan Sun for discussions and funding from the European Union Seventh Framework Programme under grant agreement no604391 Graphene Flagship.

References

To continue reading please sign in or create an account.

Don't Have An Account?