High-Throughput Palladium Precatalyst Guide

24 Pre-weighed Palladium Precatalysts

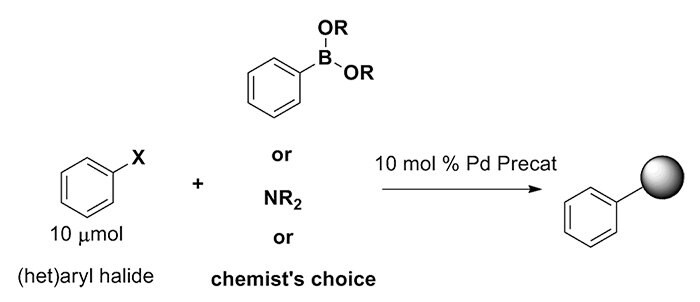

Useful for: Suzuki-Miyaura; Buchwald-Hartwig; Negishi; Heck ; Sonagashira; Borylation; Ni/Pd co catalyst screen

Materials required - set up: depending upon your design, you need at a minimum:

- 1 mylar bag from the KitAlysis 24 Pd Precatalyst Reaction Screening Kit and you will use the following components:

- 24 x 1 pre-weighed catalysts in glass vials loaded with stir bars and topped with cap mat (included)

- 2 empty 4 mL reaction vials (included)

- 1 NEW KitAlysis 24-Well Reaction Block Replacement Film (included)

- KitAlysis 24-Well Reaction Block (sold separately)

- KitAlysis Benchtop Inertion Box (sold separately) or glove box/glove bag

- KitAlysis Torque Screwdriver Set (sold separately)

Additional (not included) items needed:

- Pipette (0-100 µL) & tips

- 1 (1 mL) syringes with long needles

- Your substrates

- Nitrogen (or Argon): from hood line or tank

- 1 hot plate with stir capabilities

- 1 stir plate (or hot plate to be used without heat)

- HPLC vials, 96-well HPLC auto sampler block, or TLC plates.

Solutions & slurries to make: Go to the online user set-up page to enter molecular weights into the downloadable excel file.

Set Up Procedure:

- Preheat your hot plate to the desired temperature. It is highly recommended to use an oil bath or second reaction block to hold temperature and avoid spiking.

- Place a NEW KitAlysis 24-Well Reaction Block Replacement Film on reaction block lid and verify all holes, including the temperature probe hole, line up with the corresponding holes on the film.

- Check all screws to ensure they are not stripped. Replace any stripped screws with provided replacements.

- Place the KitAlysis Benchtop Inertion Box with tubing connected to inert gas onto the second, non-heated stir plate (see KitAlysis Benchtop Inertion Box set-up for details)

- Place KitAlysis 24-Well Reaction Block with lid into KitAlysis Benchtop Inertion Box. Start nitrogen flow and purge 5 minutes. Leave nitrogen flowing for remainder of set up.

- Weigh all substrates and solid bases into the empty 4 mL reaction vials according to recipe (provided in the downloadable excel file) omitting solvent and liquid bases. Add one stir bar to each vial mixture. Label vials to keep track.

- Partially open the lid on the KitAlysis Benchtop Inertion Box. Ensure that one vial is placed in the center hole on both sides of the inertion box. This vial placement allows for the best flow of inert gas (remove lids from the solid mixtures before placing them into the recommended holes, keeping the lids in the Inertion Box for later use if needed).

- Transfer the capped, 24-vial, preloaded catalysts into the reaction block making sure to load it according to the matching diagram on the packaging and the Reaction Block (A1 in top left corner). Leave the mat on.

- Load solvent ampules into ampule holes located along the bottom of the Inertion Box, below the Reaction Block. You can also use anhydrous SureSeal(ed)100 mL bottles of solvent with a nitrogen fed manifold needle attached. Rigorously degassed, ampulized solvents are available for many solvents, specially made for KitAlysis and sold separately to allow customization.

- Once all components are in the KitAlysis Benchtop Inertion Box, close the lid and purge for an additional 5 minutes. Leave nitrogen flowing for remainder of set up.

- Purge needle and syringe in a nitrogen diffuser hole 2x by pulling and then pushing plunger. Using purged needle and syringe, add required solvent amounts to open substrate mixture vials from either ampules or SureSeal bottles. DO NOT add liquid base solutions to any substrate mixture-it is added directly to each reaction vial separately as the last step.

- Stir mixtures until in solution (1-2 min). For slurries, see “additional tips” below.

- While mixtures are stirring, carefully remove the cap mat from the 24-vial, preloaded catalysts in the reaction block.

- Dose stock solutions according to your reaction design (100 µL of 0.1M solutions to each vial is standard)Dose 100 µL of “DMAc Substrate Mixture A” to vials A1-A6 according to scheme below.

- You may have a very small amount of excess solution remaining for each mixture. Save it as a reaction

standard for HPLC/TLC later - After all substrate mixtures and base have been dosed according to recipe, take the KitAlysis 24-Well Reaction Block lid and line up the screws with the holes in the plate. Ensure the temperature probe holes line up on both the lid and the block.

- Screw on lid according to directions and pattern shown in the “additional tips” section below. Before removing KitAlysis 24-Well Reaction Block from the Inertion Box, ensure that the lid is evenly sealed onto the base. Do this visual check as you go along to avoid having to unscrew the lid and screw again.

- Once completely sealed, remove the KitAlysis 24-Well Reaction Block from the Inertion Box. Place on preheated hot plate with probe through the lid and inserted into the block. Make sure the probe is all the way into the bottom of the block to avoid overheating. Heat at desired temperature overnight stirring at or near 300 rpm.

- Make the quench solution in a bottle with a replaceable lid following the recipe below for HPLC analysis. TLC is also possible.

- At reaction completion, follow the below Work-Up Procedure

Quench Solution Recipe

- 49 mL CH3CN

- 1 mL AcOH

- 15.4 mg Biphenyl (KitAlysis Internal Standard provided in the kit)

Note: This recipe makes 50 mL which is enough stock solution for all one screening sets in the KitAlysis 24 Pd Precatalyst Reaction Screening Kit. The amount of internal standard is 10 mol%. So a big product peak to small internal standard indicates a good reaction.

Work-up Procedure and Analysis

- Cool Reaction Block. Remove lid using small, non-torque KitAlysis screwdriver.

- Check each vial for solvent loss, and record.

- Aliquot 500 µL of prepared quench solution to each vial.

- Replace lid, tighten middle screw and stir on stir plate (NO HEAT) for 2-3 minutes. DO NOT INVERT BLOCK.

- After 2-3 minutes of stirring, let plate rest (without stirring) for 5 minutes to allow insoluble material to settle out of solution to the bottom of the vials.

- While plate is resting, add 700 µL of acetonitrile to each 24 individually labeled (A1, A2 etc,) HPLC vials or to each of 24 wells of a 96-well HPLC/UPLC auto sampler block (see “additional recommended materials” below for suggestions on the auto sampler block and cap mat.

- Remove lid on KitAlysis 24-Well Reaction Block carefully.

- Using a clean pipette each time, remove a 25 µL aliquot from each vial into corresponding HPLC vials or HPLC block . Be careful to pull material from the top of the vials to avoid any precipitate.

- Run on HPLC auto sampler. You may need to adjust the amount of acetonitrile from the suggested 700 µL to accommodate your unique HPLC system.

Additional Tips:

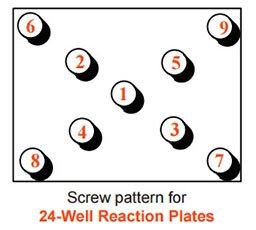

Sealing the Plate-screwing down the cover

Sealing the plate properly is critical to success. The key is light, even pressure to the lid of the block to keep the cover flat while sealing.

- Line-up screws making sure that the base and lid temperature probe holes line-up in the KitAlysis 24-Well Reaction Block.

- Initially flush: Using your thumb and forefinger, press the lid of the box until it becomes flush with the vials. Then, using the KitAlysis Torque Screwdriver, insert screws until flush, but not tight, with the top of the box, following the cross pattern provided below. Check to see that the lid is evenly sealed onto the base on all sides. Do this visual check to avoid having to unscrew the lid and screw again.

- Tighten: Repeat the same pattern until the KitAlysis Torque Screwdriver “clicks” indicating complete tightness. Go around the block once more for a final check to ensure all screws are tight.

Probe for hot plate does not fit into reaction block hole

Use a small oil bath or other metal block (for best results) in the back of the hot plate and place the probe in there. Place reaction block as close to the center of the hot plate as possible for more even stirring.

Slurry Additions

Due to narrow opening of pipette tips, slurry additions will result in blockages. To aid in uniform dosing, simply snip off the end of the tip at the first marker (~10 mm). To ensure an evenly dispersed aliquot, it is critical that the mixture is stirring well while you draw aliquots for dosing into the corresponding reaction vial.

Materials

To continue reading please sign in or create an account.

Don't Have An Account?