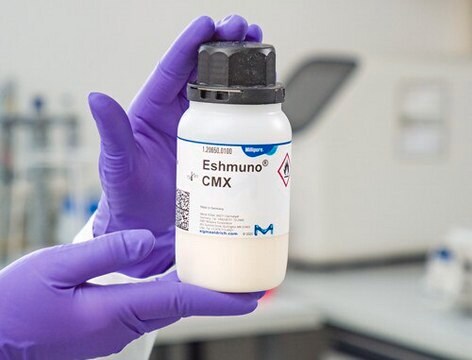

추천 제품

Quality Level

ligand

(Trimethylammoniumethyl)

무균

sterile (Caustic Stable)

제품 라인

Eshmuno®

양식

resin

특정 분석물질

MAbs

파라미터

1000 cm/hr flow rate

1000 cm/hr max. flow rate

8 bar max. pressure

기질 활성군

polymer, polyvinyl ether

평균 입자 크기

85 μm

용량

150 mg binding capacity (BSA/mg of resin)

~150 mg, BSA binding capacity

유사한 제품을 찾으십니까? 방문 제품 비교 안내

일반 설명

특징 및 장점

- Purification of acidic and neutral proteins and peptides from different sources, including plasma

Superior productivity for downstream processing of biomolecules

- High flow rate versus pressure-flow behavior

- Excellent removal of impurities, such as HCP, leached Protein A, and viruses

- Robust and safe packing procedures

- Strong chemical stability

포장

- 1.20079.0100: Eshmuno® Q Resin 100ml

- 1.20079.0010: Eshmuno® Q Resin 10ml

- 1.20079.0500: Eshmuno® Q Resin 500ml

- 1.20079.5000: Eshmuno® Q Resin 5L

분석 메모

Microscopic evaluation: Spherical particles, no agglomerates, no fines.

Extractable matter (water): ≤ 0.08 %

Ionic capacity: 90 - 190 µeq/ml

Performance test (conalbumin): 9 - 19 mS/cm

Performance test (human serum albumin): 20 - 30 mS/cm

Pressure drop(column: ID=1.6 cm, L=10 cm at 5 ml/min): ≤ 1.0 bar

Protein binding capacity(bovine serum albumin): 120 - 190 mg/ml

Particle size (50-120 µm): ≥ 80 %

Particle size (d50): 75 - 95 µm

Cerium: ≤ 30 µg/g

Endotoxins: ≤ 1.00 EU/ml

TAMC (total aerobic microbial count): ≤ 100 CFU/ml

TYMC (total yeast and mould count): ≤ 100 CFU/ml

법적 정보

신호어

Warning

유해 및 위험 성명서

Hazard Classifications

Flam. Liq. 3

Storage Class Code

3 - Flammable liquids

WGK

WGK 1

Flash Point (°F)

95.0 °F

Flash Point (°C)

35 °C

Emprove® 프로그램이란?

Emprove® 프로그램은 자사의 필터 그리고 일회용 구성품, 제약용 원료 물질 및 시작 물질의 종합적이고 빈틈없는 문건을 제공하는 체계입니다.

무료 - 다운로드하려면 로그인하십시오

무료 - 다운로드하려면 로그인하십시오

구독하거나 수수료를 지급하시면 이용 가능

문서

See case study examples of how to optimize chromatographic purification of plasmid DNA for Biopharmaceutical Applications.

A custom-designed cost model is used to explore the economics of vaccine manufacturing across several different modalities including mRNA. The model enables greater process understanding, simulates bottlenecks, and helps to optimize production efficiency.

Influenza vaccines are commonly made using egg-based and cell-based manufacturing strategies. Find step-by-step information on the manufacturing process for each method.

Learn more one the attenuated viral vaccines manufacturing process: cell culture, clarification, nuclease treatment, chromatography, and sterile filtration.

관련 콘텐츠

맞춤형 바이러스 백신 제조는 협력을 통해 바이러스가 가진 고유의 문제를 해결합니다.

This technical article breaks down the adenovirus vaccine manufacturing process and provides a case study on developing an accelerated and cost-effective single-use adenoviral vector vaccine.

Learn more on mAb downstream processing, more specifically polishing chromatography and the relevant associated products.

자사의 과학자팀은 생명 과학, 재료 과학, 화학 합성, 크로마토그래피, 분석 및 기타 많은 영역을 포함한 모든 과학 분야에 경험이 있습니다..

고객지원팀으로 연락바랍니다.