339164

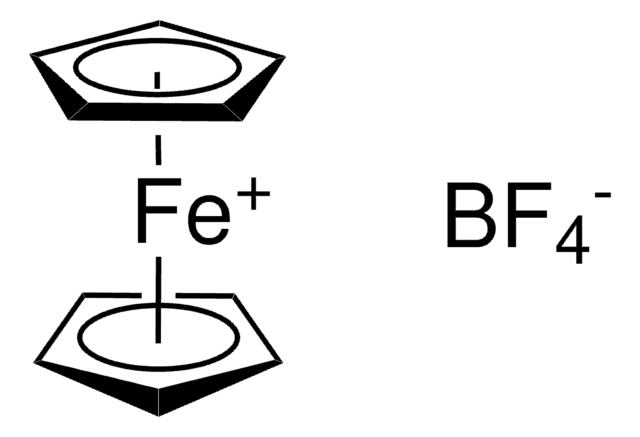

Bis(cyclopentadienyl)cobalt(II)

Synonym(s):

Cobaltocene

About This Item

Recommended Products

form

powder or crystals

solid

Quality Level

reaction suitability

core: cobalt

mp

176-180 °C (dec.) (lit.)

storage temp.

2-8°C

SMILES string

[Co].[CH]1[CH][CH][CH][CH]1.[CH]2[CH][CH][CH][CH]2

InChI

1S/2C5H5.Co/c2*1-2-4-5-3-1;/h2*1-5H;

InChI key

PXFGMRZPRDJDEK-UHFFFAOYSA-N

General description

Application

- As a dopant to prepare encapsulated carbon nanotubes with high thermoelectric conversion efficiency.

- As a CVD precursor to fabricate cobalt oxide thin films for various applications.

- As a redox-active anode species in Li-based redox flow batteries to achieve higher energy densities and energy efficiencies.

- As a catalyst for controlled/“living” radical polymerization of methylmethacrylate.

signalword

Danger

hcodes

Hazard Classifications

Carc. 2 - Flam. Sol. 2 - Muta. 2 - Resp. Sens. 1 - Skin Sens. 1

Storage Class

4.1B - Flammable solid hazardous materials

wgk_germany

WGK 3

ppe

Eyeshields, Gloves, type P3 (EN 143) respirator cartridges

Choose from one of the most recent versions:

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Customers Also Viewed

Articles

Atomic layer deposition meets various needs including semiconductor device miniaturization and nanoparticle coating.

The diversity of applications and nanostructured materials accessible using ultrasonic spray methods are highlighted in this article.

Spintronics offer breakthroughs over conventional memory/logic devices with lower power, leakage, saturation, and complexity.

Ultrasonic spray pyrolysis produces scalable nanomaterials like metal oxides and quantum dots for diverse applications.

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service