445746

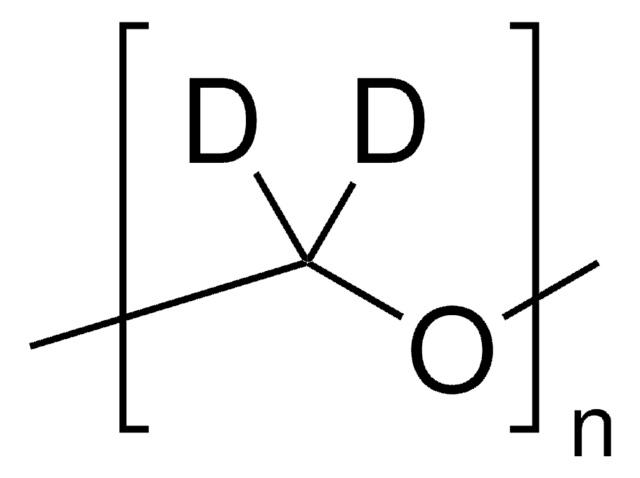

Poly(methyl methacrylate)

average Mw ~350,000 by GPC

Synonym(s):

PMMA, Poly(methacrylic acid methyl ester)

About This Item

Recommended Products

form

powder

Quality Level

autoignition temp.

580 °F

mol wt

average Mw ~350,000 by GPC

reduced viscosity

150-160 cm3/g(20 °C)(lit.)

acid number

<1 mg KOH/g

transition temp

Tg (DSC) 105 °C (midpoint)

solubility

alcohols and aliphatic hydrocarbons: insoluble

esters, ketones, aromatics and glycol ethers: soluble

density

1.17 g/mL at 25 °C

InChI

1S/C5H9O2/c1-4(2)5(6)7-3/h1-3H3

InChI key

PMAMJWJDBDSDHV-UHFFFAOYSA-N

Looking for similar products? Visit Product Comparison Guide

General description

Application

Features and Benefits

Storage Class

11 - Combustible Solids

wgk_germany

nwg

ppe

Eyeshields, Gloves, type N95 (US)

Choose from one of the most recent versions:

Certificates of Analysis (COA)

Don't see the Right Version?

If you require a particular version, you can look up a specific certificate by the Lot or Batch number.

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Customers Also Viewed

Articles

Professor Aran discusses engineering graphene-based materials through careful functionalization, enabling diverse applications.

Self-healing soft electronic materials enable autonomous repair, reducing waste and costs in electronic devices.

Fluorescence quenching microscopy visualizes 2D materials like graphene and MoS2 rapidly, inexpensively, and with high fidelity.

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service