23320-U

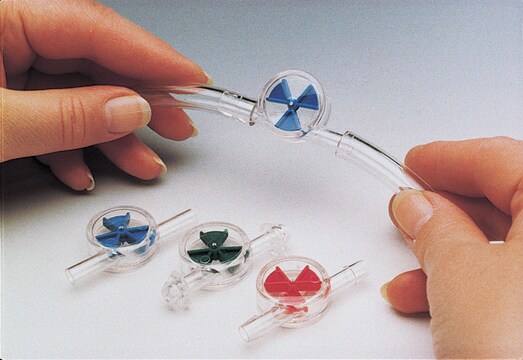

Supelco Rotameter

flow rate 0-244 mL/min, with needle valve

Synonym(s):

flow meter, 0-244 mL/min

Sign Into View Organizational & Contract Pricing

All Photos(1)

About This Item

UNSPSC Code:

41112500

NACRES:

SB.54

Recommended Products

parameter

0-244 mL/min flow rate

Looking for similar products? Visit Product Comparison Guide

General description

Rotameters are suitable for low flow measurement. They can only be used on clean fluids. A typical rotamter has a tapered metering tube which is mounted vertically with small end at the bottom and a float which is free to move within the tube. The fluid to be measured enters at the bottom of the tube, passes upwards around the float and out at the top. The increase and decrease of flow causes the float to rise higher or drop to low respectively. The flow rate is hence determined by direct observation of the position of the float in the metering tube.

This rotameter is designed for the accurate regulation of gas flow, providing measurement at the same time. This versatile unit includes four interchangeable floats, each with a different working range. Simply install the float required for the application. Standard flow tables in mL/min at STP are included.

The rotameter is easy to mount. Alternatively, it can be installed on a tripod assembly (order tripod assembly separately). Available with or without needle valve.

Specifications:

Float Upper Flow Rates

0-33 mL/min. Rotameter

0-110 mL/min. Rotameter

0-246 mL/min. Rotameter

0-454 mL/min. Rotameter

The rotameter is easy to mount. Alternatively, it can be installed on a tripod assembly (order tripod assembly separately). Available with or without needle valve.

Specifications:

- Max. Pressure: 200 psig (13.8 bar)

- Max. Temp.: 250 °F (121 °C)

- Connections: 1/8 in. female NPT (use connector to male NPT fittings to connect into gas delivery system)

Float Upper Flow Rates

0-33 mL/min. Rotameter

- Glass Float: 6 mL/min.

- Sapphire Float: 8 mL/min.

- Stainless Steel Float: 17 mL/min.

- Carboloy Float: 33 mL/min.

0-110 mL/min. Rotameter

- Glass Float: 19 mL/min.

- Sapphire Float: 30 mL/min.

- Stainless Steel Float: 61 mL/min.

- Carboloy Float: 110 mL/min.

0-246 mL/min. Rotameter

- Glass Float: 49 mL/min.

- Sapphire Float: 73 mL/min.

- Stainless Steel Float: 137 mL/min.

- Carboloy Float: 246 mL/min.

0-454 mL/min. Rotameter

- Glass Float: 92 mL/min.

- Sapphire Float: 140 mL/min.

- Stainless Steel Float: 264 mL/min.

- Carboloy Float: 454 mL/min.

Application

Calibrated Supelco Rotameter is suitable in mixing medical grade breathable gas with either oxygen or nitrogen.

Storage Class

11 - Combustible Solids

wgk_germany

WGK 3

flash_point_f

Not applicable

flash_point_c

Not applicable

Choose from one of the most recent versions:

Certificates of Analysis (COA)

Lot/Batch Number

Sorry, we don't have COAs for this product available online at this time.

If you need assistance, please contact Customer Support.

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Customers Also Viewed

Bela G. Liptak

Flow Measurement (1993)

Laura K Smoyer et al.

Genetical research, 82(3), 163-170 (2004-05-12)

The Triplo-lethal locus (Tpl) of Drosophila is both triplo-lethal and haploinsufficient, but the function of the locus is unknown. We have examined Tpl-aneuploid embryos and find that, in both trisomics and monosomics, the midgut shows extensive cell death and the

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service