256439

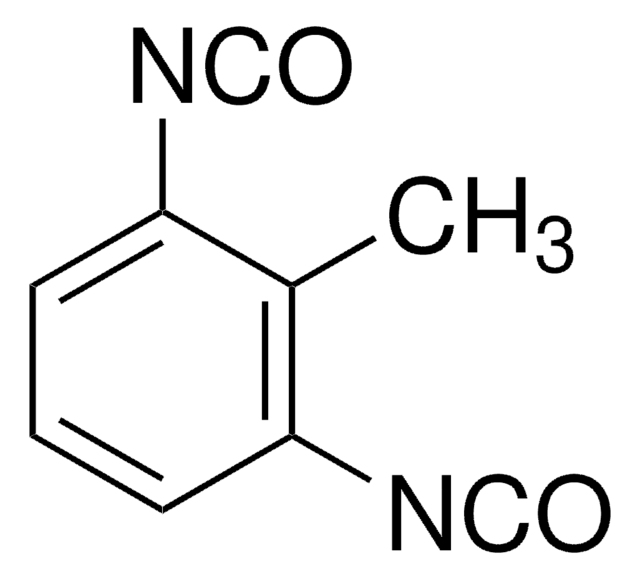

4,4′-Methylenebis(phenyl isocyanate)

98%

Synonym(s):

4,4′-MDI, Bis(4-isocyanatophenyl)methane

About This Item

Recommended Products

Quality Level

assay

98%

form

solid

reaction suitability

reagent type: cross-linking reagent

bp

200 °C/5 mmHg (lit.)

mp

42-45 °C (lit.)

density

1.18 g/mL at 25 °C (lit.)

storage temp.

−20°C

SMILES string

O=C=Nc1ccc(Cc2ccc(cc2)N=C=O)cc1

InChI

1S/C15H10N2O2/c18-10-16-14-5-1-12(2-6-14)9-13-3-7-15(8-4-13)17-11-19/h1-8H,9H2

Looking for similar products? Visit Product Comparison Guide

Related Categories

General description

Application

- Polyurethane cationomers, that are applicable in medical implants.[1]

- A prepolymer for preparing self-healable polyurethane elastomers.[2]

signalword

Danger

Hazard Classifications

Acute Tox. 4 Inhalation - Carc. 2 - Eye Irrit. 2 - Resp. Sens. 1 - Skin Irrit. 2 - Skin Sens. 1 - STOT RE 2 Inhalation - STOT SE 3

target_organs

Respiratory system

Storage Class

11 - Combustible Solids

wgk_germany

WGK 1

flash_point_f

411.8 °F - closed cup

flash_point_c

211 °C - closed cup

ppe

dust mask type N95 (US), Eyeshields, Faceshields, Gloves

Choose from one of the most recent versions:

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Customers Also Viewed

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service