663301

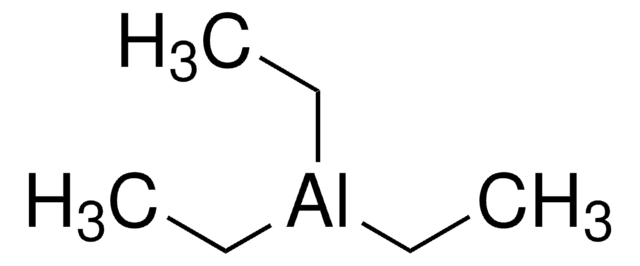

Trimethylaluminum

packaged for use in deposition systems

Synonym(s):

Aluminum trimethanide, TMA

About This Item

Recommended Products

vapor pressure

69.3 mmHg ( 60 °C)

Quality Level

description

heat of vaporization: ~41.9 kJ/mol (Dimer)

form

liquid

reaction suitability

core: aluminum

bp

125-126 °C (lit.)

127 °C/760 mmHg

20 °C/8 mmHg

56 °C/50 mmHg

mp

15 °C (lit.)

density

0.752 g/mL at 25 °C (lit.)

SMILES string

C[Al](C)C

InChI

1S/3CH3.Al/h3*1H3;

InChI key

JLTRXTDYQLMHGR-UHFFFAOYSA-N

Looking for similar products? Visit Product Comparison Guide

General description

Application

- A chemical vapor deposition precursor to fabricate PbSe quantum dot solids for optoelectronic devices.

- An aluminum precursor for the flame synthesis of alumina nanofibers.

- A reagent for efficient synthesis of allenes.

signalword

Danger

hcodes

Hazard Classifications

Eye Dam. 1 - Pyr. Liq. 1 - Skin Corr. 1B - Water-react 1

supp_hazards

Storage Class

4.2 - Pyrophoric and self-heating hazardous materials

wgk_germany

nwg

flash_point_f

No data available

flash_point_c

No data available

ppe

Faceshields, Gloves, Goggles, type ABEK (EN14387) respirator filter

Choose from one of the most recent versions:

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Customers Also Viewed

Articles

Atomic layer deposition (ALD) showcases innovation in novel structure synthesis, area-selective deposition, low-temperature deposition, and more.

Atomic layer deposition meets various needs including semiconductor device miniaturization and nanoparticle coating.

Atomic Layer Deposition (ALD) technology ensures uniform coating on complex 3D surfaces with precise chemisorption cycles.

Nanocomposite Coatings with Tunable Properties Prepared by Atomic Layer Deposition

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service