1.20079

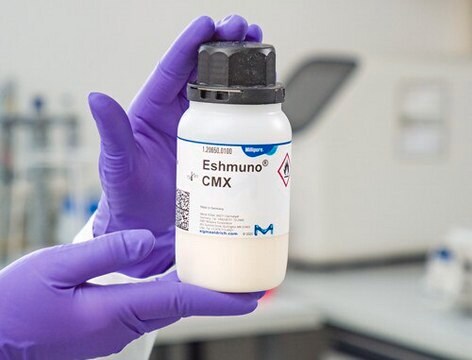

Eshmuno® Q Resin

Eshmuno® Q

Synonym(s):

Eshmuno® Q

About This Item

Recommended Products

Quality Level

ligand

(Trimethylammoniumethyl)

sterility

sterile (Caustic Stable)

product line

Eshmuno®

form

resin

specific analyte(s)

MAbs

parameter

1000 cm/hr flow rate

1000 cm/hr max. flow rate

8 bar max. pressure

matrix active group

polymer, polyvinyl ether

mean particle size

85 μm

capacity

150 mg binding capacity (BSA/mg of resin)

~150 mg, BSA binding capacity

transition temp

flash point 35 °C (own results)

density

1 g/cm3 at 20 °C

application(s)

recombinant protein

vaccine development

separation technique

anion exchange

mixed mode

storage temp.

2-30°C

Looking for similar products? Visit Product Comparison Guide

General description

Features and Benefits

- Purification of acidic and neutral proteins and peptides from different sources, including plasma

Superior productivity for downstream processing of biomolecules

- High flow rate versus pressure-flow behavior

- Excellent removal of impurities, such as HCP, leached Protein A, and viruses

- Robust and safe packing procedures

- Strong chemical stability

Packaging

- 1.20079.0100: Eshmuno® Q Resin 100ml

- 1.20079.0010: Eshmuno® Q Resin 10ml

- 1.20079.0500: Eshmuno® Q Resin 500ml

- 1.20079.5000: Eshmuno® Q Resin 5L

Analysis Note

Microscopic evaluation: Spherical particles, no agglomerates, no fines.

Extractable matter (water): ≤ 0.08 %

Ionic capacity: 90 - 190 µeq/ml

Performance test (conalbumin): 9 - 19 mS/cm

Performance test (human serum albumin): 20 - 30 mS/cm

Pressure drop(column: ID=1.6 cm, L=10 cm at 5 ml/min): ≤ 1.0 bar

Protein binding capacity(bovine serum albumin): 120 - 190 mg/ml

Particle size (50-120 µm): ≥ 80 %

Particle size (d50): 75 - 95 µm

Cerium: ≤ 30 µg/g

Endotoxins: ≤ 1.00 EU/ml

TAMC (total aerobic microbial count): ≤ 100 CFU/ml

TYMC (total yeast and mould count): ≤ 100 CFU/ml

Legal Information

signalword

Warning

hcodes

Hazard Classifications

Flam. Liq. 3

Storage Class

3 - Flammable liquids

wgk_germany

WGK 1

flash_point_f

95.0 °F

flash_point_c

35 °C

Certificates of Analysis (COA)

Search for Certificates of Analysis (COA) by entering the products Lot/Batch Number. Lot and Batch Numbers can be found on a product’s label following the words ‘Lot’ or ‘Batch’.

Already Own This Product?

Find documentation for the products that you have recently purchased in the Document Library.

Articles

See case study examples of how to optimize chromatographic purification of plasmid DNA for Biopharmaceutical Applications.

Influenza vaccines are commonly made using egg-based and cell-based manufacturing strategies. Find step-by-step information on the manufacturing process for each method.

A custom-designed cost model is used to explore the economics of vaccine manufacturing across several different modalities including mRNA. The model enables greater process understanding, simulates bottlenecks, and helps to optimize production efficiency.

Learn more one the attenuated viral vaccines manufacturing process: cell culture, clarification, nuclease treatment, chromatography, and sterile filtration.

Related Content

This technical article breaks down the adenovirus vaccine manufacturing process and provides a case study on developing an accelerated and cost-effective single-use adenoviral vector vaccine.

Learn more on mAb downstream processing, more specifically polishing chromatography and the relevant associated products.

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others.

Contact Technical Service