A Review of Mesoporous TiO2 Thin Films

Jinshu Wang, Junshu Wu, Hongyi Li

1The Key Lab of Advanced Functional Materials, Ministry of Education China, 2School of Materials Science and Engineering, Beijing University of Technology, Beijing 100124, China

Introduction

Titanium dioxide (TiO2) is an important n-type semiconducting material that shows interesting characteristics such as photoswitchable surface wettability, high photocatalytic activity, bistable electrical resistance states and high electron drift mobility. The photocatalytic activity, strong oxidizing properties and photoresponsive behavior of titania find applications as antifogging, self cleaning and disinfecting coatings on medical devices, food preparation surfaces and building materials. Titanium dioxide is the most widely used white pigment because of its brightness and very high refractive index and is found in all kinds of paints, printing ink, plastics, paper, synthetic fibers, ceramics, electronic components along with food and cosmetics. Among the many TiO2-based materials with distinct structural and geometrical features, mesoporous TiO2 architectures represent an important class of novel materials which have recently attracted a renewed interest in both fundamental and applied materials research.1-4 Hard and soft-templating syntheses are the two most widely used methods to prepare this class of porous materials.

The hard-template assisted route involves the use of colloidal particles, for example, polymeric beads, and anodic alumina membranes. The nanostructures are formed on the inner or outer surfaces of the templates using sol-gel casting or other particle adsorption methods. Removal of these templates then generates these unique porous materials.

The soft-template assisted route involves the use of ionic organic surfactants or nonionic polymeric surfactants which self-assemble into a diversity of supermolecular structures including, spherical micelles, hexagonal rods, lamellar liquid crystals and other assemblies in solution, driven by non-covalent weak interactions such as hydrogen bonding, van der Waals forces and electrostatic interaction between the surfactants and the building blocks. These assemblies are then used as soft templates to tune the pore structure and size of porous materials.

In this paper, we discuss recent advances in the preparation of various TiO2 porous structures via hard and soft-templating routes. Specifically, we focus on recent developments in TiO2 mesoporous thin films in a combined sol-gel and evaporation-induced self-assembly (EISA) process.

Hard-Templating Syntheses of TiO2 Porous Structures

Hard-templating is the most commonly used approach for the preparation of TiO2 porous materials over the past two decades.5,6 Porous inorganic materials are found in the natural world. Such structures, with periodic pores, are remarkable for their morphological and crystallographic control. They can be used to fabricate ordered three-dimensional (3D) TiO2 porous structures with a crystalline framework, high specific surface area and tailored pore structure through controlled nucleation and templating.

Sandhage et al. demonstrated that an intricate, 3D, nanocrystalline rutile TiO2 (635065, 637262, 204730) structure was generated with the morphology and nanoscale features inherited from a chitin-based Morpho butterfly wing template.7 In order to obtain hierarchical TiO2 porous structures with the synergistic advantages of mesoporous and macroscale morphologies, Moon et al. introduced a method to engineer hierarchical TiO2 materials consisting of meso and macroscale pores using a dual templating method.8 Monodisperse polystyrene (PS) colloidal particles were injected into the template. After coating with TiCl4 (254312, 208566) solution, both the holographic and colloidal dual templates were calcined in an air environment. This resulted in anatase TiO2 structures with macropores (250 nm in diameter) due to the removal of the holographic patterns. It also resulted in mesoscale pores (50 nm in diameter) due to the removal of the PS particles.

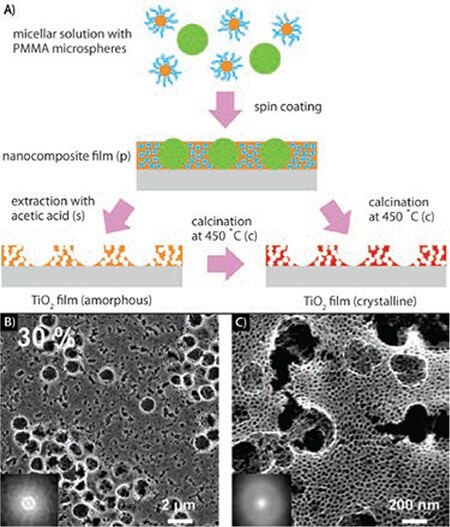

Buschbaum et al. prepared hierarchically mesoporous sponge-like structure TiO2 films with partially interconnected pores of a circular shape and with a diameter of about 30-40 nm. They did this by combining poly(methyl methacrylate) (445746, 182265, 182230), PMMA microsphere secondary templating and sol-gel chemistry with an amphiphilic diblock copolymer (PDMS-b-MA(PEO)) as a structure-directing agent (Figure 1A).9 A phase separation in an amphiphilic block copolymer was induced in this approach, while the Ti precursor was chemically linked to one of the blocks. The structure in the sol-gel solution was transferred to solid thin films with TiO2 particles embedded in microspheres.

With increasing PMMA microsphere addition, the number of surface depressions created in the films increased, together with the tendency for agglomeration. Additionally, the size of the mesopores was decreased (Figure 1B, C). This was attributed to the complex interplay of all the components involved in the sol-gel process by the addition of a second templating polymer. This influenced the phase separation in existing primary structures. The mesopore size can be further decreased by selecting a decent block copolymer as a structure-directing agent. By using amphiphilic triblock copolymer Pluronic® P123 (EO20PO70EO20) combined with a hard templating process, Xu et al. synthesized ordered arrays of mesoporous titania spheres with mesopore size in the range of ~35 nm.10 The titania precursor solution containing EO20PO70EO20 was infiltrated into the spherical macropores of the PMMA mesh which was prepared by using silica opal. Ordered mesoporous TiO2 sphere arrays were finally obtained by removing the PMMA mesh template and the triblock copolymer surfactant. However, the elimination of solid hard-templates increases the cost and risk of large-scale manufacture, and thus lots of challenges are left to scientists in the discipline domains.

Figure 1. A) Illustration of the preparation route for hierarchical structuring of TiO2. B, C) SEM images of TiO2 films with 30% amounts of PMMA microspheres added to the sol-gel solution.9 Reprinted with permission from Kaune, G; et al. Applied Materials 2009, 1(12), 2862-2869. Copyright 2009 American Chemical Society.

Soft-Templating Syntheses of TiO2 Porous Structures

EISA offers excellent opportunities for the reproducible synthesis of mesoporous metal oxide films. The self-assembly of block copolymer, driven by evaporation, offers an excellent opportunity in directing mesostructures for inorganic species. Selection of appropriate starting materials, especially the Ti source and block copolymer, is vital in the successful preparation of highly organized mesoporous structure of TiO2 films. The suitable Ti source is quite limited. Available titanium alkoxides include titanium ethoxide (Ti(OEt)4) (244759), titanium isopropoxide (Ti(O-iPr)4) (687502), and titanium butoxide (Ti(OBu)4) (244112), listed in an order of increasing reactivity in hydrolysis. Compared with other Ti sources such as TiF4 (/US/en333239), they show predominant performances in controlling the homogeneity of the initial solution and final size of TiO2 crystallites on the nanoscale.11

The ideal block copolymers for EISA are molecules with a polar hydrophilic head which is attracted to water and a hydrophobic hydrocarbon chain which is attracted to oil. In water, the hydrocarbon chains tend to self-associate to minimize contact with the water molecules, leading to the formation of various aggregates. Organized soft-template systems such as micelles, reverse micelles, vesicles, liquid droplets, etc. have been widely exploited to provide effective routes to grow porous structures.12,13

For the suitable block copolymers, commercially-available amphiphilic poly(ethylene oxide)-block-poly(propylene oxide)-block-poly(ethylene oxide) (PEO-PPO-PEO) triblock copolymers, typically Pluronic® P123 (PEO20PPO70PEO20, EO = ethylene oxide, PO = propylene oxide, MW = 5800) (435465) and F127 (PEO106PPO70PEO106, MW= 12,600) (P2443), consisting of a central hydrophobic PPO chain and two hydrophilic PEO tails, have been widely used as the structure-directing agents for the construction of highly organized mesoporous structures for TiO2, where P and F stand for the physical forms of paste and flake, respectively.14

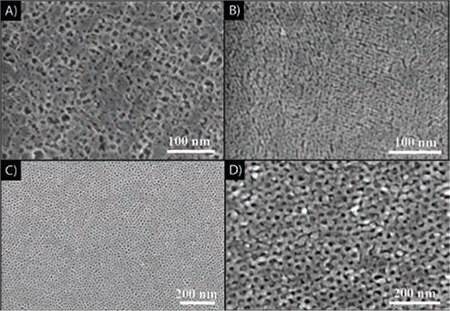

Rankin et al. combined P123 surfactant templating and polypropylene glycol (PPG) (202304, 202355, 81380) phase separation to generate hierarchically porous titania thin films.15 As shown in Figure 2A, PPG behaved as a hydrophilic compound and was incorporated into the polar titanate-rich phase at the initial low-temperature period. However, during high-temperature drying, PPG switched to being hydrophobic and drove the phase separation process, either due to a change in the entropic driving force during polymerization of the titanate species or the enthalpic driving force associated with PPG interactions with other species. A high mass ratio of PPG to P123 (M = 0.3) induced uniform mesopores with a high degree of long-range order and hexagonal symmetry (Figure 2B-D).

Figure 2. A) Formation mechanism of thin films with hierarchical porous architecture. B-D) High-magnification TEM images of calcined TiO2 thin films prepared with mass ratios of PPG to P123 (M) = B) 0.3, C) 0.5, or D) 1. Scale bar = 50 nm.15 Reprinted with permission from Wu, Q.; et al. Langmuir 2011, 27(15), 9557-9566. Copyright 2011 American Chemical Society.

In our group16,17, we prepared high-quality mesoporous titania thin films with good thermal stability (up to 600 °C) by using triblock copolymer Pluronic® F127 as the structure-directing agent and tetrabutyl titanate as the inorganic precursor. The excellent thermal stability is correlated to the thick wall of the mesostrcture. The use of F127 as the templating agent was the premise for the formation of the thick walls and larger pore diameters in the mesostructure.

The F127 was a unique surfactant owing to its high molecular weight with long hydrophilic PEO and hydrophobic PPO segments. This offered the possibility of the formation of thicker walls and larger pore diameters in the mesostructure.

The block copolymer micelle was composed of a core dominated by PPO and a corona dominated by PEO segments. The core of the micelles was believed to be free of water, while the corona was hydrated. The pore size was, to a large extent, dependent on the effective volume of the hydrophobic core (PPO) of the micelles. The wall thickness was determined mainly by the hydrophilic corona (PEO).

In addition, the use of a non-aqueous solvent and Ti(OBun)4 as the inorganic precursor was very important. During the synthesis of sol, the strong chelating agent, acetylacetone (10916) and acid solvent, permitted control of the reactivity by avoiding fast hydrolysis and condensation of the precursor in solution. Furthermore, anhydrous solvent depressed the reactivity of the precursor. Under the “dry conditions”, the slow hydrolysis and condensation speed of the inorganic precursor preferred the formation of oligomeric Ti-oxo species or titania clusters. This was the premise for the formation of thick and solid inorganic walls in the framework. These small entities associate preferentially with polyethylene oxide (PEO) (372773, 372781, 372838) moieties in the self-assembly process.

Figure 3 shows the transmission electron micrographs of the TiO2 thin films. Figure 3(A) revealed that the film could maintain homogeneous and well-ordered mesostructure even after calcination at temperature of 600 °C. The mesopores of the film presented with an elliptical shape because of the growth of the crystalline grains. HRTEM image of the film (Figure 3B) showed that the film was composed of high-crystalline nanoparticles. The pore size and wall thickness of the mesostructure were in the range between 6-9 and 9-12 nm, respectively. The ultra thick and robust walls resulted in the good thermal stability of the obtained film. A selected-area electron diffraction (SAED) pattern (inset Figure 3B) of the sample confirmed that these crystallites were anatase.

Figure 3. A) TEM image and B) HRTEM image of the synthesized mesoporous TiO2 thin films prepared with F127 calcined at 600 °C; The inset of Figure 2B is the SAED pattern of the calcined sample.

We also found that the kinds of block copolymer and ions used had a great impact on the thermal stability of TiO2 films. Figure 4 shows the scanning electron micrographs of the films prepared with different block copolymers and prepared with thiourea ethanol solution, using F127 as the block copolymer. As shown in Figure 4A and B, after calcination at 500 °C, the films prepared with P123 and Brij®58 (EO20CH16H) (P5884) had low quality mesoporous structure, i.e., some mesoporous structures had deformed and collapsed, whereas those prepared with F127 had exhibited a uniform pore size distribution (Figure 4C). This indicates that the block copolymers which had long hydrophilic PEO and hydrophobic PPO segments were favorable for the formation of thick wall structures. However, when 2.5% (mol) thiourea (T8656, T7875) was added to the solution, the films that were confirmed by the doping of N and S partly lost the uniform mesoporous structure, with some particles on the surface of the film (Figure 4D).

The hydrolysis of the Ti-alkoxide precursors in the acidic solution would result in the formation of nanometer sized Ti-oxo clusters.18 These were preferentially associated with the hydrophilic PEO block of F127 micelles which formed the hybrid amorphous mesostructure. When thiourea was added to the acidic solution, thiourea might have a chemical reaction with water absorbed from the air to form H2S and NH3. The H2S and NH3 produced can then react with oxygen in the air and hydrochloric acid to produce sulfur and ammonium chloride.

The excess amount of NH4Cl (254134, 326372) caused the collapse of the mesoporous microstructure since NH4+ of NH4Cl adsorbed at the micellar interface and changed the micellar curvature. The hydrophilic poly(ethylene oxide) (PEO) blocks became gradually more dehydrated. This increased the effective size of the hydrophobic core at the expense of the hydrophilic corona, leading to the change of the micelle shape from spherical to columnar. As a result, the micelles were difficult to assemble with inorganic-oxo species, leading to the loss of the mesoporous structure.

Figure 4.SEM images of the TiO2 thin films prepared with A) P123, B) Brij58, C) F127 and (D) F127 together with thiourea followed by 500 °C calcinations.

Application of Mesoporous TiO2

Porous solids possessing large specific surfaces and easily accessible cavities have found wide applications in heterogeneous catalysis, sorption, separation, gas sensing, optoelectronics, host-guest chemistry molecular electronic devices. In this article, we mainly introduced the application of mesoporous TiO2 into the photocatalysis field. Semiconductor photocatalysis is an established, significant and still-expanding area of research which has led to numerous commercial products, such as self-cleaning glass, tiles and paint.

The current commercial manifestations of photocatalysis usually utilize a layer of the semiconductor photocatalyst, invariably anatase titania (637254, 232033, 248576).19 The photocatalytic mechanism for the semiconductor is that, upon excitation, a conduction-band electron and a valence-band hole separate. The hole then initiates an oxidative reaction while the electron initiates a reductive reaction. Thus, organic compounds coming in contact with TiO2 films can be destroyed either through direct oxidation by the trapped holes or attack by hydroxyl groups.

Methods adopted for assessing and characterizing the activities of TiO2 films include: (i) the discoloration of dyes, such as methylene blue (MB) and methyl orange (MO) dissolved in aqueous solution; (ii) the photomineralization of a thin solid film of a wax-like substance, such as stearic or palmitic acid and (iii) the photo-oxidation of gas phase pollutants.

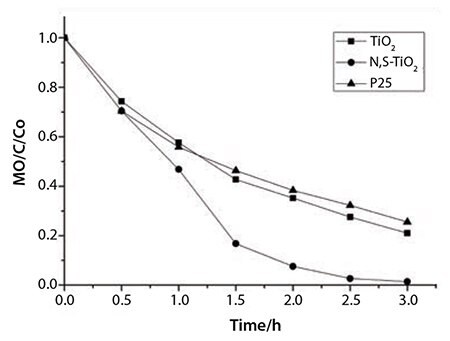

In our work, we evaluated the photocatalytic activity of mesoporous TiO2 by photodegradation of methyl orange solution. Figure 5 shows the decomposition of MO aqueous solution of pure mesoporous TiO2 and N, S doped mesoporous TiO2 prepared with thiourea under UV illumination. As shown in Figure 5, compared with the standard sample P25, both pure mesoporous TiO2 and N, S doped TiO2 exhibited higher photocatalytic activity, especially for the co-doped sample. The MO solution was degraded completely in 3h.

The high porosity, the large pore size and the high pore volume of the mesoporous TiO2 samples, which were favorable for the adsorption of organic molecules in the mesostructure, led to the improvement of the organic degradation capability. Furthermore, the UV-visible reflection result of the samples indicated that the N, S doping improved the photoadsorption of the light. As a result, the N, S doped mesoporous TiO2 showed the highest photocatalytic activity among these three samples.

Figure 5.The photocatalytic activity of the pure and N,S co-doped mesoporous TiO2 samples together with P25.

Summary

The TiO2 mesoporous materials discussed above, which possess interesting properties and potential applications, constitute an important domain of the nanostructure family. Future developments will rely on facile fabrication processes and novel synthetic methods. Specifically, more work needs to be done to address the combination of sol-gel chemistry with other synthesis techniques to improve both in terms of morphology, purity, composition and yield control and in terms of flexibility for pore size choice.

Acknowledgments

This work is financially supported by Beijing Innovation Talent Project (PHR201006101); Beijing Municipal Commission of Education Key Foundation (KZ2010100050001); National Natural Science Foundation of China (51002004); Beijing New Century Hundred, Thousand and Ten Thousand Talent Project, State key Laboratory of Electronic Thin Films and Integrated Devices (UESTC: KFJJ201001).

References

To continue reading please sign in or create an account.

Don't Have An Account?